Medical Waste Autoclave

The steam autoclave is the most popular and cost effective medical waste treatment technology. Unlike the incinerator, the autoclave technology does not generate any hazardous combustion air pollutant emissions, such as hydrochloric acid, carbon monoxide,dioxin, metal (particulate matter), etc. The autoclaved medical waste by product is sanitized and safe for landfill disposal. Medical waste that is properly steam autoclaved is rendered noninfectious and safe for disposal at sanitary landfills.

The working process of SINOMAC medical waste sterilization autoclave

1. Bin Loading

Autoclave bins are loaded with infectious waste and are transferred into the autoclave vessel for treatment. After the door is closed, automatically or manually; the operator is able to start the preprogrammed cycle by pushing a “start” button.

2. Treatment

After the autoclave door is closed the following steps are performed by the preprogrammed controller. The first step is the pre-vacuum process. A vacuum of 24"- 28" Hg. is pulled during the pre-vacuum to evacuate the air from the vessel and to expedite and insure good steam penetration into the infectious medical waste. The second step is heating with steam when the temperature rises to 134-138 C. degree and the pressure reaches 3.0-3.8 bars. The waste load is then soaked at temperatures to meet the state regulations and to effectively treat the waste to render it noninfectious and safe for final disposal. The third step is cooling.It is performed through a steam condenser resulting in no steam being released into the atmosphere. The forth is the post vacuum cycle which removes residual steam from the autoclave, flashes residual liquids drying the waste. The fifth step is atmosphere into the sterilization autoclave to insure the pressure reducing .

3. Unloading

Once the cycle is completed, the autoclave will illuminate a green light showing the cycle is complete and the door is ready to be opened. The operator will then unload the autoclave and the bin dumper will empty the bins into a compactor or a shredder.

4. Shredders

SINOMAC Autoclave Systems shredders are heavy duty, single or double stage shredders to meet required particle size. Each knife configuration has been designed to suit the material for maximum throughputs and optimum size.

SINOMAC Autoclave is the best-class in Medical Waste Sterilization Field

SINOMAC is a professional manufacturer in design, engineering and manufacturing high-tech autoclave system for decontamination of infectious wastes.We have supplied high-tech autoclave system to the medcial waste treatment industry for many years.Our treatment technology systems are designed for high vacuum and high pressure capability,which are subject to a pre-vacuum cycle, pulsating saturated steam cycle, and a post vacuum cycle to facilitate faster and more uniform penetration of steam into the medical waste to be treated. The most important is our ability to provide high quality equipment at competitive price has made us the best-class supplier in the medical waste sterilization autoclave market.

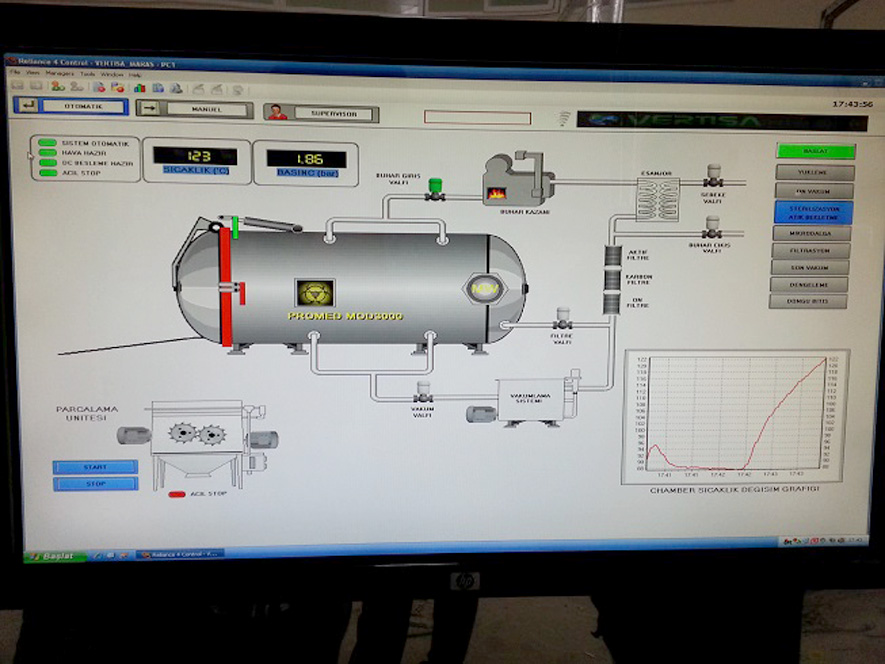

TPC software for medcial waste treatment

SINOMAC autoclave equipped with advanced Thermal Processing Control (TPC) system. The system has the login of user permissions, parts sensor selection, curing process curve setting, calling, saving and printing, full automatic operation, real-time data monitoring, recording, storage and printing,

system status monitoring, event alarm, quality analysis, and so on.

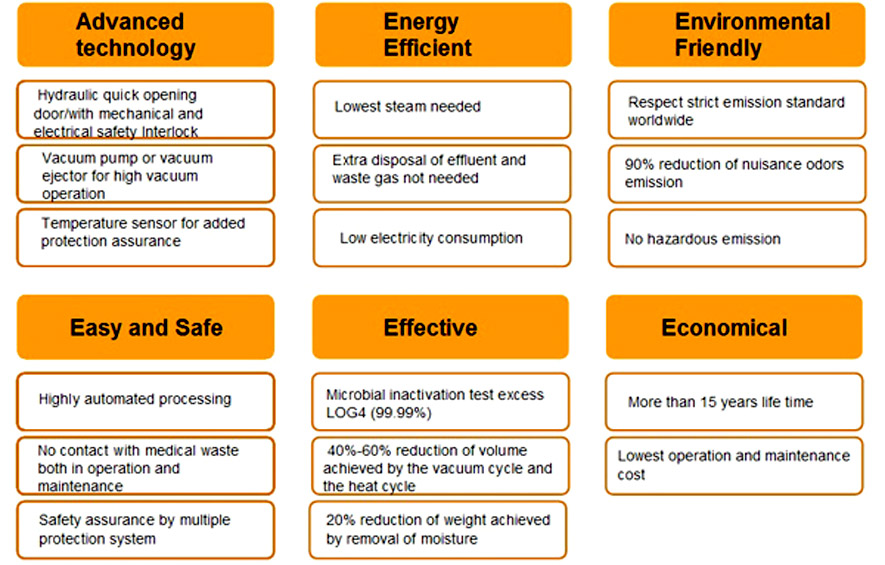

Advantages of SINOMAC Medical Waste AUTOCLAVE

Detailed Production Process

In order to guarantee the quality of medical waste autoclave, we manufacture the equipment under the strict process construction guidance, each working procedure, we do it carefully; for the parts, we use only the highest quality materials.

|  |  |

Meet the Different Size Requirements

SINOMAC can design and build the most size medical waste autoclaves, the diameter from 1.5 meter to 4 meters, and the length from 1 to 21 meters.

Complete Auxiliary System

SINOMAC can offer full and complete auxiliary system, including vacuum system, steam boiler system,waste loading trolley, shredding machine and any other auxiliary.

Global Service and Various Manufacture Standard

SINOMAC can manufacture the autoclave according to Chinese standard

Global Turn-key Project Service

SINOMAC team has full experience and technical ability to offer global turn-key project service. You don’t have to be worried about the installation and system commissioning. We can carry out a professional and careful train for users