Wood Autoclave

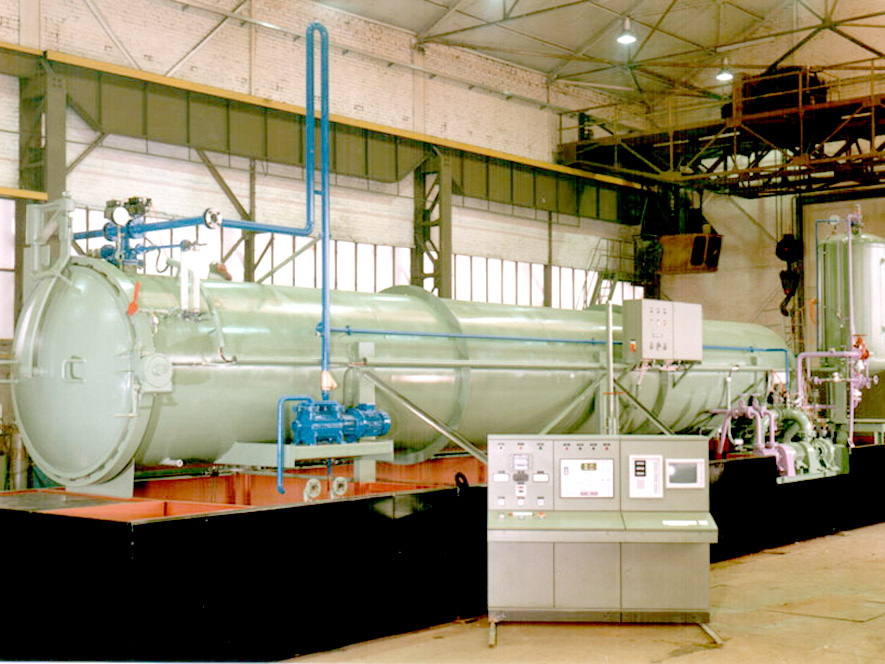

Wood autoclave is divided into two major series of product, which is wood impregnation and carbonization. wood impregnation autoclave is mainly processing for wood preservation, degreasing and dyeing; wood carbonization autoclave is mainly used for wood physical modification; carbonization of wood by heating and pressurizing, achieving the effect of antisepsis and ultraviolet prevention, more energy saving and environmental protection. SINOMAC wood autoclave can realize automatic operation, perfect docking with production line, safe and efficient.

The Usage of SINOMAC Wood Impregnation Autoclave

| The vacuum pressure leaching process is widely used in the world for the treatment of wood preservative, degreasing, dyeing and so on. This process is the most important and effective way of industrial treatment for wood preservation. It will put wood in a special sealed pressure container tank, and put the antiseptic agent into the wood inside under pressure, and at the same time, heat treatment. It realized the physical process of introducing preservatives into wood, and completed the chemical reaction process of some effective components of preservatives and starch, cellulose and sugar in wood, and destroyed the survival environment of bacteria and insects that caused wood decay. SINOMAC wood impregnating autoclave series products can achieve fully automatic operation, perfect connection with production line, safe and efficient, and impregnation effect is superior to other similar equipments, energy saving, environmental protection and no pollution. |

SINOMAC Wood Carbonization Autoclave

| With the improvement of people's quality of life and environmental protection, we questioned the safety of using chemicals to treat wood and formulated some restrictive regulations for its use. The pure physical modified wood products are getting more and more extensive market space, and the deep carbonization technology of wood occupies an important position. Based on the careful study of the existing high temperature heat treatment equipment abroad and the improvement of domestic technology, SINOMAC has pioneered the development of Wood Carbonization autoclave and processing technology in China, which is the ideal processing equipment and technology for deep carbonization wood. |  |

Advantages of SINOMAC TPC Software

SINOMAC Wood autoclave is equipped with advanced TPC control system. This system is developed on base of researching many control systems at home and abroad for many years. It has been very mature and popular. The system has basic functions as below: login permission, sensor options, technology curve setting/calling/saving/printing, automatic/manual performance, real-time data monitoring/record/saving/printing, parts conditions monitoring, alarm, quality analysis, report forms, etc.

● Control system Option: PLC+HIM or PLC+PC

Vaccum/High pressure immersion treatment process

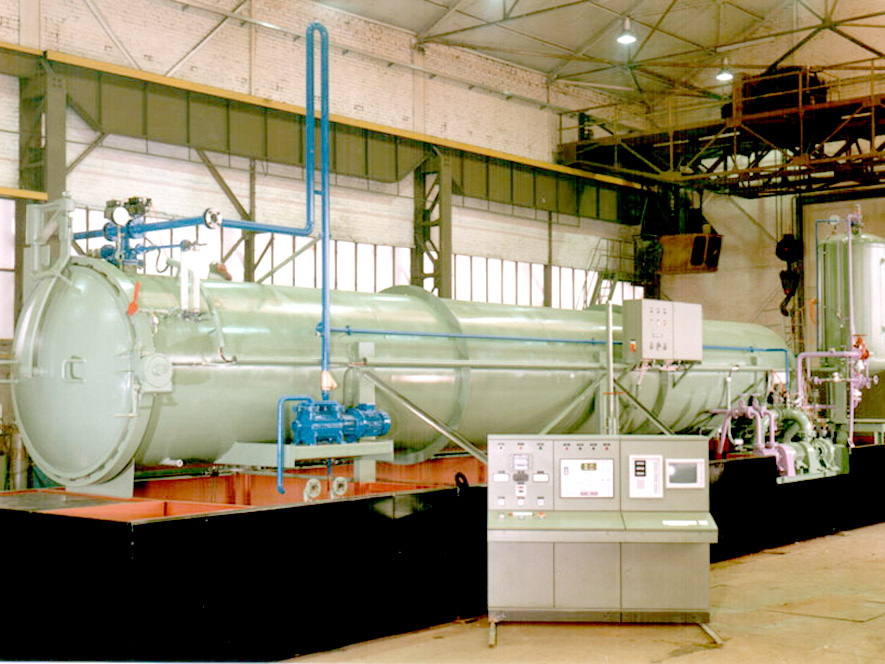

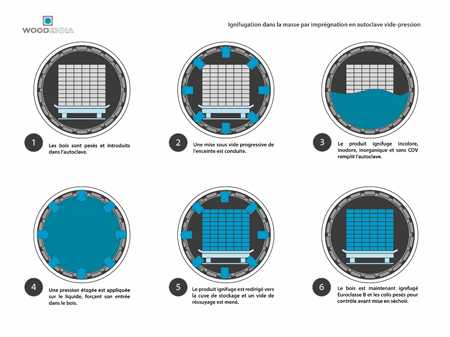

1.Full cell process

| A. Initial vacuum |

Characteristics of the full cell process

When the soaking tank is turned into a vacuum, a part of the air in the wood is also extracted. The resistance of the preservative into the wood is relatively small. With pressure, the preservative is easier to enter the wood, so the preservative is filled with wood cells. There are many antiseptic doses, which may retain the maximum number of preservatives.

2. Empty cell process

| A. Initial air pressure |

Characteristics of the empty cell process

The initial air pressure instead of the initial vacuum forced the air into the wood cells and compressed, and the antiseptic of the pressure when exposed to pressure was more than the full cell method. The maximum penetration depth is reached by the minimum amount of absorption, and the drug is saved and the cost is reduced. Full cell process has a large number of chemicals present in the cell cavity, and empty cell method cell cavity is empty or contains only a small amount.

Technical advantages of SINOMAC Wood Autoclave

◆ Optimal design and manufacture

◆ Hydraulic side and upper opening for the door, mechanical safety interlocking device

◆ Vacuum system operated by a high vacuum

◆ Temperature and pressure protection device

◆ TPC control software based on PLC

◆ Complete set of assembly components and systems, simple and convenient

◆ The preservatives are impregnated completely and thoroughly.

◆ Full automatic unmanned operation

Detailed Production Process

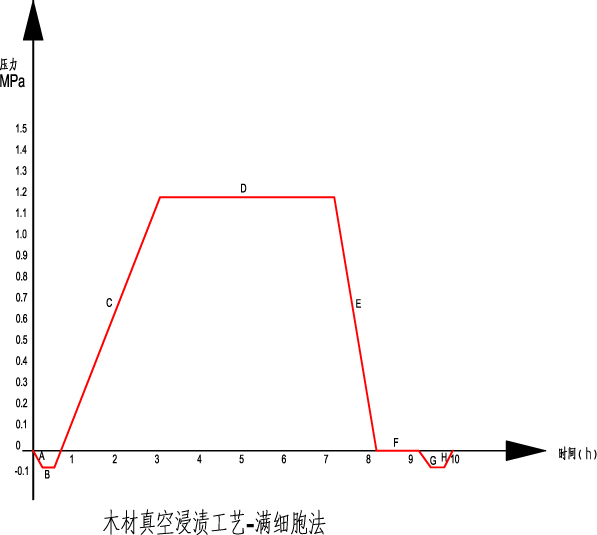

In order to guarantee the quality of wood autoclave, we manufacture the equipment under the strict process construction guidance, each working procedure, we do it carefully; for the parts, we use only the highest quality materials.

|  |  |

Meet the Different Size Requirements

SINOMAC can design and build the most size wood autoclaves, the diameter from 1.5 meter to 4 meters, and the length from 1 to 21 meters.

Complete Auxiliary System

SINOMAC can offer full and complete auxiliary system, including vacuum system, steam boiler system,wood loading trolley, supercharger and any other auxiliary.

Global Service and Various Manufacture Standard

SINOMAC can manufacture the autoclave according to Chinese standard, certainly we can offer autoclave to be approved by ASME, PED and AD standard. And the electrical system can be certified by standard of CE and UL.

Global Turn-key Project Service

SINOMAC team has full experience and technical ability to offer global turn-key project service. You don’t have to be worried about the installation and system commissioning. We can carry out a professional and careful train for users