Composite Curing Ovens

Composite Curing Ovens are used to cure high strength, low weight carbon composite materials. Carbon fiber is light, yet stronger than steel and is used to manufacture aerospace, automotive, wind power and many other industry parts. SINOMAC composite curing ovens are an excellent solution to processing composites parts with an out-of-autoclave solution.

Complete Composite Curing System

Thermal curing is a critical step in manufacturing quality composite materials. Traditionally, most composite parts required autoclaves for proper curing. Today, low cost out-of-autoclave curing of aerospace-grade composite parts is possible using a vacuum bagging system with a walk-in batch oven. The process is precisely controlled and monitored to ensure void-free composite parts.

SINOMAC provides complete composite curing systems that include a custom configured oven, integrated multi-port vacuum system, and excellent control system with our TPC software. The system meets AMS2750, BAC5621, NADCAP and AS9100 requirements.

Composite Curing Oven Technology

The anchor of the SINOMAC composite curing system is an oven that delivers exceptional temperature uniformity for perfectly cured parts. It uses horizontal and combination recirculating airflow to ensure uniform temperatures throughout the oven. A high-volume fan circulates air through louvered, aluminized steel walls to create a constant horizontal airflow across all sections of the oven.

Flexible and customizable to specific composite curing requirements

Tight uniformity, standard at +/-5°C or better

Electrically heated or gas fired

Custom airflow to optimize heat transfer to unique molds

Two maximum temperature ratings available:260°C and 343°C (500°F and 650°F)

Standard sizes from 52 to 960 cubic feet.(1,472 to 27,184 liters)

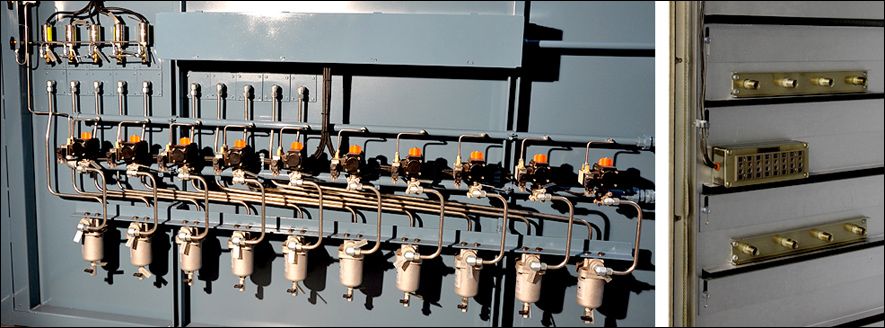

Integrated multi-port vacuum systems and jack panels

The SINOMAC composite curing system offers an integrated, multi-port vacuum system and jack panels to connect as many thermocouples as needed for monitoring the curing process.

Jack panel thermocouple arrays to fully monitor product.

Vacuum ports can be added for easy connection to the vacuum bag within the oven

Vacuum monitoring with data recording throughout cure cycle

Vacuum pump and all required components for complete system, including vacuum level regulation

Stringent vacuum stability tolerances<1” Hg loss per hour at 25”Hg

TPC (Thermal Processing Control) software for composite curing

Tight process control and monitoring is critical for consistent quality parts. TPC software fully controls the curing process and documents all process information, providing traceability and validation of part quality.

PC-based system with Ethernet communication

All relevant process data is saved on system PC and can be accessed from plant computer system

Standard and customized reporting capability to validate process

Vacuum system can be monitored and controlled from display