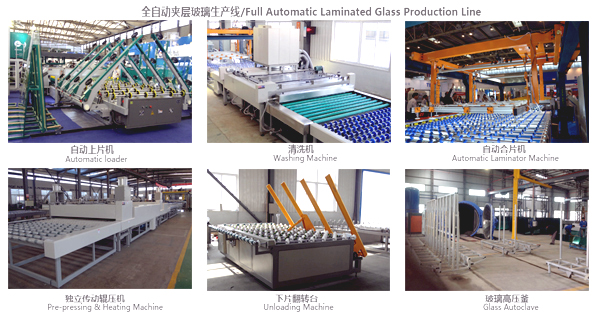

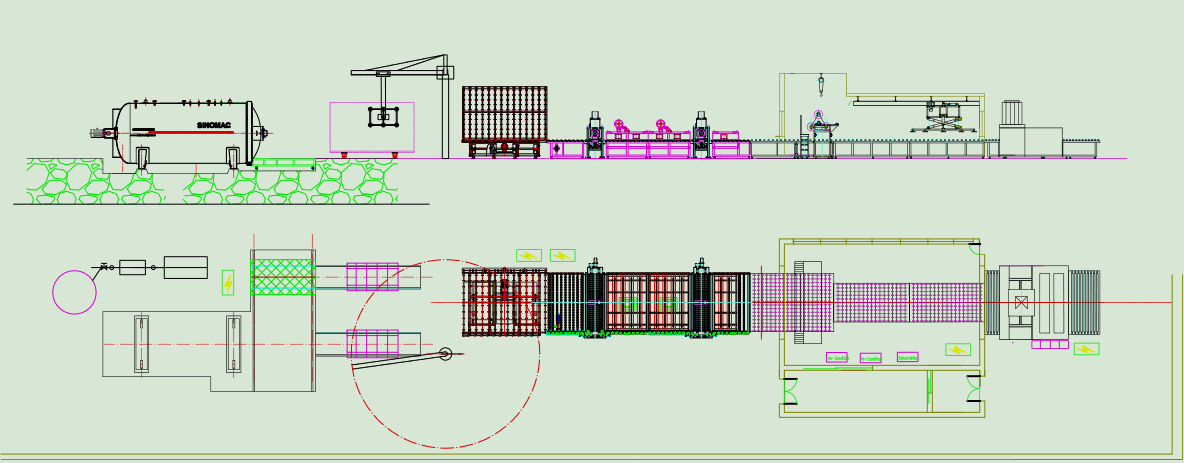

1. Basic Solution for Full Automation Glass Lamination Line

1.1 Solution Includes the Following Machines :

JCX-1 | Full automation glass loading machine |

JCX-2 | Mechanical rotary tilting table for loading |

JCX-3 | Glass washing machine |

JCX-4 | Automatic positioning table |

JCX-5 | Automatic suction hanger |

JCX-6 | Extendable assembling table |

JCX-7 | Film spreader |

JCX-8 | Transition conveying table I |

JCX-9 | Forced convection pressing machine |

JCX-10 | Transition conveying table II |

JCX-11 | Mechanical rotary tilting Table for unloading |

JCX-12 | Glass autoclave |

1.2 Working Process of This Lamination Line

1.2.1 For Primary Float Glass

Loading by Full-Auto Glass Loading Machine → Washing →Automatic Assembly → Pre-heating and pressing →Unloading by Mechanical rotary tilting table→ High pressing into autoclave→ Final product

1.2.2 For Small Processing Glass Sheet

Loading on Mechanical rotary tilting table → Washing →Automatic Assembly → Pre-heating and pressing →Unloading on Mechanical rotary tilting table→ High pressing into autoclave→ Final product

2. General Features of Laminated Line

The whole line adopts the advanced communication of industrial Ethernet network and is in centralized control by computer assisted in PLC and all display and operation are in touch screen of control box in the clean room. The hardware based on Siemens Smart 200 ensures the high efficiency and stability of the whole system. The frequency converters control all motors to ensure the stability of acceleration and deceleration at high speed. The non-contact sensors ensure that there is sensitive response, high precision and no wear and tear in the transmission. The glass autoclave adopts a fully intelligent TPC control system, according to the set temperature and pressure curve, the whole production process is completed automatically.

2.1 The Automatic Loading System

A light crane with vacuum sucker holder or automatic loading equipment ensures that the glass is safely transported from the glass storage rack to the front-end of the lamination line, and then the glass is positioned on the mechanical rotary tilting table and transmitted to the cleaning machine through rollers.

2.2 Washing Machine

Washing machine can wash glass sheet with thickness of 3-25mm. The upper rubber rollers, brush rollers and air-knives etc. can be automatically adjusted. The upper section of the machines can be elevated by 450mm for clean and repair. The brush rollers are driven by motors with upper and lower separately. Allocation of one soft brush and three hard brushes (can be lifted when needed) in the upper washing sector is designed for washing hard LOW-E glass, coated glass without damaging the coating. Two Stainless steel air-knives, the blower equipped with muffle cotton and air feeding filter screen pack ensures plenty of air, less noise and the good drying effect.

2.3 Clean Room

The clean room is a two-floor building composed of composite sandwich plates and steel structure. The clean room is on the ground floor and the PVB or SGP film storage room is on the second floor. Also there is another room for air conditioning machine and humidity machine. All ambient temperatures and humidity are controlled there.

2.4 Automatic Assembly Machine

The cleaned glass enters the automatic fast positioning machine at max. speed and it is automatically positioned longitudinally and horizontally through a group of positioning sensors. The automatic sucker hanger, equipped with traceless suckers will lift and position the glass. The transmission unit sends the glass to the assembly position through precise straight rails. Operator can choose a suitable PVB film on the PVB spreader. Then the spreader can automatically lay the film in compliance with the glass size. The next glass will be placed accurately on the top the ready glass. So now the laminated glass is ready. By pressing a button, the laminated glass can be sent fast to the pre-pressing section, while the assembly position is empty for next glass. The whole process is automatic, high precision, high efficiency and good stability.

2.5 Film Spreading Machine

Film spreading machine can load 3-8 PVB or SGP film and it can achieve electric laying and collecting film. It is convenient to choose the film according to the specification of glass sheet. In addition, according to the requirements of users, the spreader can be equipped with automatic cutting unit to achieve film horizontal cutting; also we can provide suitable lifting equipment for loading film into the spreader.

2.6 Forced Convection Pressing Machine

The roller presser’s heating mode is infrared radiation heating and nickel-chromium alloy heater heating. As well, there is a forced convection system in the heating box. The front and back two pairs of large pressure rollers are driven independently by four motors, worm reduction gearbox, linear bearing, guide pillar and encoder. The closed loop control can realize the synchronous rotation of the large pressure rollers and conveying rollers. This structure design ensures the best effect of pre-pressing the laminated glass under the high production efficiency. The whole machine is controlled by Siemens PLC of S7 series and comes with the touch screen display and operation. According to the glass thickness, the pressure roller clearance and prepressing pressure can be set separately, and the optimized parameters such as speed and temperature can be configured to realize automatic setting and operation.

2.7 Unloading Machine

The laminated glass from the pressing machine runs to the unloading machine and a rotary sucker hanger sucks the glass to the glass trolley and then the glass trolley is put into the glass autoclave.

2.8 Glass Autoclave

High pressure section uses forced convection glass autoclave, PLC automatic control, HIM interface, ensuring safety ,reliable, high efficiency and energy saving.

2.8.1 Adopting advanced partition heating, graded cooling structure, with forced convection system, achieves truly energy saving and high efficiency.

2.8.2 The accurate PLC control system and HIM interface make the operation simple and convenient

2.8.3 TPC (Thermal processing control) software, makes whole work be clear at a glance. The software contains: process control, data exchange, security protection, quality control, alarm output, etc.

3. Model and Specification

Model | Max. Glass Size (mm) | Min. Glass Size (mm) | Glass Thickness (mm) | Total Power (KW) | Capacity (M2//8h) |

SN-JCX2060A | 2000×6000 | 420×300 | 4-80 | 302.5 | 1200 |

SN-JCX2560A | 2500×6000 | 420×300 | 4-80 | 335.5 | 1500 |

SN-JCX2580A | 2500×8000 | 420×300 | 4-80 | 358 | 1800 |

SN-JCX3080A | 3000×8000 | 500×400 | 4-80 | 503 | 2000 |

SN-JCX3280A | 3200×8000 | 500×400 | 4-80 | 565 | 2350 |

Note: Capacity is based on laminated glass size: 4mm+0.38mm+4mm